The First World War had provided a hiatus for some in the field of architecture; others had seized the opportunity to express the use of new materials and economic design. Industrial buildings were designed through necessity and economy, the availability of reinforced concrete had provided a means for this.

The Kahn designed “daylight “factory may have proved an efficient, opportune and economic means of building in this period. Some may have appreciated the new “Concrete Aesthetic” brought in by these massive unadorned and concrete frames, but in Britain it was felt perhaps to be too austere for our tastes and would benefit from a little adornment. This may be the reason that Truscon sought out Wallis Gilbert and Partners (ref.1) to collaborate with in this country. Thomas Wallis had spotted the need for efficient factory design during the war and beyond. Collaboration with Truscon would provide the leads needed. By the end of 1916, Wallis had designed three factories with Truscon, only one being built (ref.2) but all were used for advertising purposes.

In the post war years, manufacturers and builders realised the benefits and economies of these standard systems such as the daylight factory could be reconciled with the freedom of choice that volume production of a standard unit that could be customised to suit individual customers needs gave them. Wallis realised this too and devised a system of compositional features and decorative elements to soften the Truscon system for the British customer. An example of this includes the General Electric Company (ref. 3), (G.E.C), Witton works near Birmingham (1918-22), (figure 2.17). This building had a basic Truscon superstructure with muted Wallis style added “Egyptian style” (ref.4) adornment to the facade.

2.17 GEC factory, Witton, Birmingham U.K

Although expressionism had its foothold in mainland Europe, it was not necessarily enjoyed here by the British, who at this time had a reserved opinion of the “new ideas from Europe (ref.5). There was a debate between the traditionalist and the modernist camps. The former felt that the new era was best represented in Britain by an updating of traditional forms, perhaps of classical origin, without being imitative or revivalist. It was strongly supported by the continuation of “British Values “and could be described as nationalistic (ref.6). The modernists advanced an argument for uniformity, a style of architecture that could be adapted to any building type, be socially unifying, and be more representative of the new age , the technological age. It seemed likely that British architects would take a middle line using elements of both movements.

While concrete, glass and steel were arguably celebrated in Europe and the USA for example with Eugene Freysinnets’ (ref.7)Orly airport hangar (ref.8)(1921), (figure 2.18) where he demonstrated with the catenary arch (ref.9) the impressive dimensions that reinforced concrete could achieve in the hands of war-experienced engineers and with the concrete shell work of the Mexican based architect Felix Candela (ref.10).

2.18 Orly Airport Hangar

With the new construction techniques that followed on from Gropius in Europe which allowed glass to be used to full effect in the example of the Van Nelle Factory in Rotterdam (1928-30) (ref.11) (figure 2.19) and with the expression of exposed steel frame that was celebrated in the Fromm Rubber factory, Berlin (1930)(ref.12) (Figure 2.20).

2.19 Van Nelle factory, Rotterdam

2.20 Fromm Rubber factory, Germany

Although , perhaps , through the necessity of war requirements the British had embraced to some degree the concrete idea, its buildings could still effect a heavy overly substantial appearance. This was partly due to the delay in changing building regulations post 1918, and partly to the assumed contemporary notions that industrial buildings had to be solid and large areas of glass or slender concrete members could appear flimsy.

It took another early employee of Truscon, Sir E Owen Williams (ref.13) to bring forward the ideas of expressionism and extended possibilities of the use of concrete to Britain. After Truscon, he set up his own company “Williams Concrete Structures ltd” to market his own patent “Fabricrete” (ref.14). He used his wartime experience to success when he was appointed chief engineer of the British Empire Exhibition of 1924 (ref.15), (figure 2.21) and gaining a knighthood for his efforts in building large-scale quickly constructed buildings. The now demolished Wembley football stadium (ref.16) being a notable example.

2.21 British Empire exhibition buildings

However, it was an American company, namely Jesse Boots (ref.17), who commissioned him to build possibly his most noted factory, the Boots “Wets”(ref.18) building (1932) (figure 2.22) in Beeston, near Nottingham.

2.22 Boots 'Wets' factory Nottingham U.K

It was a green field site and he was working to a precise brief with production flow lines and required accommodation for precise operations and the links between these operations. The result was a highly glazed building set around two immense atria within which the production processes revolved. It was an immense four-storey slab structure building , set upon mushroom columns set back to allow the outer glass and steel curtain walling to sit uninterrupted, the production floor being lit from an vast span of bulls eye glazing panels (figure 2.23).

2.23 Boots Factory Nottingham, 'Wets' Interior

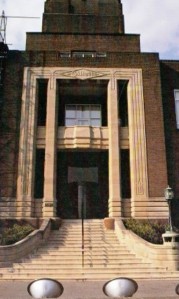

As yet, nothing had been seen like it in Britain and it could only be compared with the Van Nelle Factory in Rotterdam (1928-30). Both buildings, it should be noted, display no form of outward decoration. Possibly the only other U.K building of this genre was the factory built for the Viyella company (1932) (ref.19), coincidentally also in Nottingham (figure 2.24). The use of flat slab and mushroom column construction allowed here the use of a curtain of glass on all four sides, therefore allowing maximum penetration of natural light. This building does display a small amount of decoration with a stylised artificial stone entrance surround.

2.24 Viyella Factory Nottingham U.K

Running concurrently with the developments above, there was a move to use the factory as a commercial asset. Manufacturers in the 1920s and 1930s were operating in a fiercely competitive market trying to attract an increasing domestic demand. Many factories were located near and were visible to potential customers, either near the railways or adjacent to the increasing trunk road network. A new industry, advertising was coming of age and it was now time to put this and the factory together by using the building itself as a potentially promotional device.

Before this period, styling had been largely for fun or as a dressing. Advertising was limited to putting the company’s name on the chimney or tower, usually in white brick, as there was a limited audience for the advertising. The period between the wars saw a change in attitude as companies, at first mainly subsidiaries of American ones, with nationally known brands, sought prominent sites on the new roads around London. Good examples are Firestone tyres (1928(ref.20) ( figure 2.25) on the Great West road, Hoover in Perivale (1931-35)(ref.21) (figure 2.26) both by Wallis Gilbert and partners, Smiths potato Crisps in Cricklewood (ref.22), and Currys (then a cycle and radio manufacturer) also on the Great West road. Here again, although these buildings displayed highly decorated frontages to attract public attention, stuccoed in white “Snowcrete” cement (ref.23) and with brightly coloured faience, the plant behind usually consisting of a stark simple “Kahn” type building. In Fact the most striking part of these buildings was their use of colour, green window framing and red faience (ref.24) with Hoover, and coloured tiles on the “Pseudo-Egyptian” style tiles at Firestone, all emphasised by spotlighting at night.

2.25 Firestone tyre factory London U.K

2.26 Hoover factory London U.K

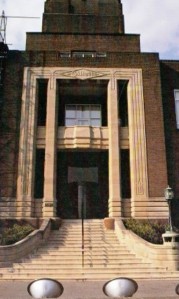

Wallis’s buildings, now often described as “Art Deco” (ref.25), or at the time often described as “Fancy”, took a lot of professional criticism by his professional peers but were liked by the public who admired their colourful facades designed to look more like a contemporary cinema rather than a dull factory. Later buildings in the same London area such as the Gillette building, Isleworth (1936) (ref.26)(figure 2.27), and the Guinness Brewery (1933-36) (ref.27), (figure 2.28) took on a more muted form with plain English brick and pared down classical ornamental elements.

2.27 Gillette Razor factory, London U.K

2.28 Guinness Brewery, London U.K

To conclude this section it is worth noting that although British factory architecture in the interwar period did not immediately embrace expressionism, there became a widespread use of reinforced concrete and steel construction, if only encouraged by firms and ideas from abroad. The blend of newer technologies and dressing up by British architects to adapt designs for their market produced a muted effect, although such examples as the Boots and Viyella factories pointed the way forward. Greater thought was given to the arrangement of plant to aid production, to increase the social welfare and well-being of the workforce.

The emergence of newer industries surrounding the automobile (ref.28), electrical (ref.29)and chemical (ref.30)industries meant a shift from the now declining textile base of the north to the newly created estates (ref.31) in the midlands and south, especially around London. This gave firms such as Wallis and Gilbert the chance to create their innovative designs. We can also witness the move from the pure use of engineers as factory designers to the emergence of the architect engineer and the architect alone.

1.

Wallis, Gilbert & Partners. The practice had been founded by Thomas Wallis (1872-I953), who in 1914 was approached by Kahncrete, the American engineering company that specialized in reinforced-concrete structures for industry and had developed its interests in the UK through a subsidiary, the Trussed Concrete Steel company (Truscon). Wallis was to have worked with Kahncrete in partnership with an American architect, Gilbert, and set up a firm styled Wallis, Gilbert & Partners — the latter being Frank Cox and, later, Wallis’ son, Douglas. The name was retained despite the fact that Gilbert never came to Britain to join the practice. Edgar Jones,

Industrial Architecture In Britain !750-1939, p. 213

2. J. Taylor and son ltd. New Southgate, London. Joan Skinner “Form and Fancy”, Liverpool, 1997, page 15.

3. G.E.C Company. In 1876, Ohio born Thomas Alva Edison opened a new laboratory in Menlo Park New Jersey, USA. Out of the laboratory came the invention a practical incandescent electric lamp. By 1890, Edison had organized his various businesses into the Edison General Electric light Company or GEC. The company established a very large engineering works in Witton, Birmingham, in 1891.The General Electric Company acquired land at Witton in 1899, and in 1901 began building its large factory together with houses for its workers. At one time, the company was employing 18,000 people on the site.. Witton, West Midlands –

4. Egyptian style: “It was the discovery of the tomb of Tutankhamen in 1922 which gave a tremendous stimulus to the interest in Egyptian styling. Tutankhamen’s treasure was of such superb design and quality that its contents became models for future Egyptian designing. The finding and opening of the tomb and the removal of the treasure was of great public interest. The style of Art Deco, much influenced by elements of Egyptian designs, came on to the scene in 1925. The Hoover building in London of 1931-32 is the most impressive example of an Art Deco factory with an Egyptian centrepiece, which is still standing. A surviving cinema is the Carleton at Islington, now a bingo hall, which had a multi-coloured Egyptian design on a white faience background. There were quite a few other Egyptianised cinemas from this period whose features included torcheres resembling slender palm shafts, an organ decorated with a Pharaoh’s head and a ladies rest room decorated with an Egyptian maiden bathing in a lotus pond” Design Influence 1

5. Joan Skinner “Form and Fancy”, Liverpool, 1997, p. 41

6. Examples of traditional buildings Edgar Jones, Industrial Architecture in Britain 1750-1939, London, 1985, page 212.

7. Eugene Freyssinet (b. Correze, France 1879; d. Saint-Martin-Vesubie, France 1962). Eugene Freyssinet was born in Corneze, France in 1879. He studied at the Ecole Polytechnique in Paris and the Ecole Nationale des Ponts et Chaussees in Paris before he was apprenticed to the engineer Rabut. He served as an engineer in the French Army from 1904 to 1907 and again from 1914 to 1918. Between his two stints in the army he worked as a road engineer for local authorities in Central France. From 1918 until 1928 he worked as Director for the Societe des Enterprises Limousin in Paris after which he established his own practice. Freyssinet created innovative architecture using reinforced concrete as his main material. More an engineer than an architect, Freyssinet still managed to introduce several collaborative architectural works. His projects generally revolved around an experimental search for a common language. His designs allowed for a free expression of materials and spaces while working within the limits of technology. Considered the “father of pre-stressed concrete”, Freyssinet died in Saint-Martin-Vesubie, France in 1962. Eugene Freyssinet – Great Buildings Online

8. Airship Hanger, at Orly (near Paris), France, 1916 (destroyed during WWII) Eugene Freyssinet – Great Buildings Online

9. Catenary Arch. In physics the catenary is the shape of a hanging flexible chain or cable when supported at its ends and acted upon by a uniform gravitational force (its own weight). The chain is steepest near the points of suspension because this part of the chain has the most weight pulling down on it. Toward the bottom, the slope of the chain decreases because the chain is supporting less weight. Catenary –

10. Felix Candela (b. Madrid, Spain 1910) Felix Candela was born in Madrid in 1910. He entered Madrid’s Escuela Superior de Arquitrectura in 1927 and graduated in 1935. Sidetracked by his political struggle against Franco, he did not practice architecture until he immigrated to Mexico in 1939. Candella believed that strength should come from form not mass. This belief led to an extensive exploration of tensile shell structures. His nickname became “The Shell Builder” because of this structural favouritism. Frequently forced to act as architect, structural engineer and contractor in order to further his work, Candella sees architects as engineers who possess the ability to design both great cathedrals and low cost housing. Felix Candela – Great Buildings Online

11. The Van Nelle Factory and Brinkman and Van der Vlugt. The Van Nelle tobacco and cocoa factory was built in Rotterdam between 1928 and 1930 by the Dutch architects, Brinkman and Van der Vlugt, and their assistant, Mart Stam. The main block can be seen as the culmination of the multi-storey framed factory, which had steadily developed without fundamental change since the Derby Silk Mill. The owners’ statement that ‘no kind of decoration is used anywhere, as it is held to have an adverse effect upon the workers’ shows the mood of the time, and how owner and architect shared a common viewpoint. Architecturally magnificent, it followed only three years after the Bauhaus building and carried through a complex programme with originality and total architectural consistency. John Winter. Industrial Architecture, London, 1970, page73.

12. Fromm Rubber and Arthur Korn. The Fagus factory was built largely of brick, Fiat and Van Nelle of reinforced concrete, and in terms of the development of light machine-made structures, these buildings were a retrogressive step from the Sheerness Boathouse. The development of the metal frame was taken up enthusiastic ally by Arthur Korn who, with S. Weitzmann, de a factory in 1930 which was a celebration of the steel frame and went far beyond the Boathouse. The three-storey-high part of this Berlin rubber factory was supported on a steel frame, clearly expressed and painted bright red: infill was of white glazed brick and steel windows imported from England. The rectangular bays of the clearly expressed frame give the building its character, and this imagery was developed by Mies van der Rohe in Chicago a decade later. John Winter. Industrial Architecture, London, 1970, page73

13. Sir Owen Williams (b. London, England 1890; d. London 1969) Evan Owen Williams was born in London in 1890. He studied engineering at London University, after which he was articled to the Electrical Tramways Co. in London. In 1912, Williams assumed a position as engineer and designer with the Trussed Concrete Company. Seven years later, he started a consulting firm. Appointed chief consulting civil engineer to the British Empire Exhibition in 1923, he received a knighthood for his services. Williams designed his buildings as functional structures sheathed with decorative facades. More an engineer than an architect, Williams produced a series of reinforced concrete buildings during the period between the wars. After World War II, he worked on developing the first plan for Britain’s motorway system. Williams died in London in 1969. Sir Owen Williams – Great Buildings Online

14. Fabricrete. Various projects using ‘Fabricrete’ including .T. Wallis & Sons factory and power station, Acton, London. Henry Boston & Sons tannery, Runcorn, Cheshire. Patent Fuel Factory, Port Talbot, West Glamorgan. British Window Glass Works, Queensborough, Cheshire. Blackstones Tractor Factory, Stamford, London. Ice factory, Grimsby, Humberside. Mappin & Webb factory, Sheffield. Fuel stages, Swansea. Fairie & Company Sugar Refinery, Liverpool. Bush House foundations, Aldwych, London. Engineering Timelines – biography – Owen Williams – selected works

15. The British Empire Exhibition opened on 23rd April 1924 and was intended to be a reassuring display of the strength of the Empire after WW1. Pavilions were built for each colony and Great Britain was represented by three major buildings plus Wembley (formerly Empire) Stadium. The exhibition covered a 216 acre site. The three major buildings were the palaces of Industry, Engineering and Arts. All were intended to be temporary. However, the Palace of Engineering wasn’t demolished until the 1970s. The facade of the Palace of Art and the whole of the Palace of Industry still stand. The original stadium, with its distinctive towers, was demolished in 2002. Reinforced concrete seems to have been chosen as the main construction material for four reasons: cost, speed of construction, appropriateness for temporary buildings (though this seems odd today) and to show the advanced state of British concrete technology. At the time of opening, the Palace of Engineering was the world’s largest reinforced concrete structure, enclosing half a million sq ft. The ten-acre Palace of Industry is slightly smaller. It consists of a series of halls with glazed pitched roofs. The columns and knees of the portal frames are cast in situ, with precast open web rafters. For the larger spans, the columns support steel lattice girders. The facades of the building are by Maxwell Ayrton, the architect of the whole exhibition complex. Other items of interest include part of the reinforced concrete elevated track for the screw-driven ‘Neverstop’ railway that took visitors around the site, which can be seen adjacent to Wembley Park Station — itself another element of the exhibitions’ construction programme. In 1933, the site owners commissioned Owen Williams to design the Empire Pool, one of the largest in the world at 200ft by 60ft. It was built on the site of the exhibition’s artificial lake. The building that housed it also enclosed 4,000 spectators. William’s concrete frames spanned 236ft clear and were exposed on the outside of the building. This building is now known as Wembley Arena. Owen Williams was knighted for his work on this site. He was 34 years old at the time. Engineering Timelines – explore … where

16.

17. Jesse Boots firm was owned by the United Drugs company.

18. Wets, applies to the type of pharmaceutical product involved, i.e. liquid forms rather than solids e.g. tablets and powders.

19. Viyella is now part of the Coats Viyella /Tootal group. Coat Viyella is the largest textile company in the UK. It consists of two divisions, Coats is the world’s leading manufacturer of sewing thread with annual turnover of GBP 1 billion. Its multinational network is made up of manufacturing units in 60 countries. Coats Viyella/Tootal

20. Firestone Tyre & Rubber Co. built in Brentford established a formula that was to be exploited successfully elsewhere on the Great West Road, and for Hoover on Western Avenue. Long office blocks, punctuated by massive pseudo-Egyptian columns, adorned with coloured tiles and entered through splendid doorways, fronted the factory sheds behind. The Firestone example was all the more remarkable when it is considered that the works had been designed in twenty-one days and a mere eighteen weeks had elapsed between the start of construction and the manufacture of the first lyre. The two-storey administration building and the four-storey warehouse were of reinforced concrete (the general contractors being Sir Robert McAlpine & Sons and the reinforced steel supplied by the Trussed Concrete Steel Co., while the single-storey factory situated between them was steel framed. The layout, arranged to accommodate the flow of mass-production pro cesses, the growing emphasis on the workforce’s welfare and the building’s dramatic appearance led The Architect to comment that: both in design and planning, British factories are noticeably improving. In design the improvement is due to the increasing realization that nothing made for human use is unworthy of the attention of the designer; and in planning to the pressure of competition necessitating efficiency both in lay-out and in detail.” Edgar Jones, Industrial Architecture in Britain! 750-1939, p. 213.

21. “The Hoover Factory, opened in 1932, advanced the Firestone composition further by the addition of two futuristic staircase towers. TI Egyptian columns, false pediment and ornate entrance were all present but more vigorously interpreted. In 1935, to raise the plant’s manufacturing capacity, a four-storey extension was added by the architects. This steel-framed building (rendered in white cement) was designed to “provide clear floor space for machinery, any necessary planning being carried out by means of movable glazed steel partitioning”. The canteen, erected in 1938, featured generous areas o externally hung glass, some of the windows curving around to form the striking entrance”. Edgar Jones, Industrial Architecture in Britain, 1750-1939, p. 214.

22. Smiths Crisps Company. The first person to manufacture crisps in the UK was a gentleman called Frank Smith of Smith’s crisps in the 1920’s. Frank Smith opened his first factory in Cricklewood, London. Potato Crisps » Potato Crisps (Interesting Facts about Potato Crisps)

23. Snowcrete. This is the trade name for an Ordinary Portland Cement where the raw materials are selected for good colour, and the clinker is ground with ceramic balls, not iron as for OPC. It can be tinted with pigments; so, should you want strawberry pink concrete this is possible. Cement, mortar and concrete FAQ

24. Faience: earthenware decorated with coloured opaque metallic glazes. MSN Encarta – Search Results – faience

25. Art deco: Style of architecture, interior design, and jewellery most popular in the 1930s that used geometrical designs bold colours and outlines.

26. “The Gillette Building , Architect Bannister Fletcher, on the Great West Road is described in The Buildings of England as of a ‘very incongruous, timidly modernistic grandeur”; In 1936 Gillette Isleworth building was constructed and officially opened on the 6th January 1937 by Sir George Broardbridge, then, The Lord Mayor of London “.Sir Banister Fletcher’s A History of Architecture

27. “The Guinness Brewery (Architect Sir Giles Gilbert Scott) at Park Royal was constructed on a landscaped open site in 1933-36 by the consulting engineers Sir Alexander Gibb & Partners, who brought in Sir Giles Gilbert Scott as architect. Scott, fresh from his acclaimed triumph at Battersea Power Station, designed and detailed the brick exteriors of the reinforced-concrete brewery blocks. The result was a powerful monumental group, vast and yet approachable and friendly.” The Twentieth Century Society

28. Automotive industries: Ford Motor Company, Dagenham, Essex, 1930. Firestone Tyre Company, q.v note 63 above. Edgar Jones, Industrial Architecture in Britain, 1750-1939, p. 209.

29. Electrical industries: Hoover q.v note 62 above, Belling lee company, Radio and electrical components, Great West Cambridge road, Enfield , 1932.Local History Industry in Enfield A History – Enfield Council Website

30. Chemical industries: Pyrene company, London 1930, Joan Skinner “Form and Fancy”, Liverpool, 1997, pp 134-137

31. Examples include Slough industrial estate 1920 and Team valley estate 1937.